5 DIY Woodworking Skills You Need to Know

Many people shy away from woodworking jobs since they haven’t done it before, or they believe that they will need to go out and buy thousands of dollars worth of tools. In fact, some basic woodworking skills can substitute for tools that are high-priced – making the endeavor you have always dreamed of potential.

Here’s a rundown of the 5 most important beginner woodworking skills that will help you get going. When you’re done, have stand desk sits.

Drilling Holes

At some point in almost any DIY project, you’re going to need to drill holes. The easiest way to do this is with a cordless drill. Cordless drills can go anywhere, last a long time, and won’t break the bank. They are also very functional from simply tightening screws quickly to drilling large holes in various materials.

Drilling holes sounds pretty simple, and it is! There’s a few tricks though that will help you drill better holes and get more use from your drill. The video below includes tips like catching dust, making guides for drill holes, making sure you drill to the right depth every time, and creating pilot holes. Armed with these tips, your holes should be more consistent in depth, make less mess, and always be in the right place.

Cutting Materials

There are a number of ways you can cut, including a hand saw, jigsaw, circular saw, table saw, and small band saw. We’ll focus on hand saws, jigsaws, and circular saws as they’re the cheapest and should work for 90% of your home projects.

- Hand saws are a good option for making quick cuts that don’t need to be perfectly straight. They do take some muscle as they are non-powered, but are perfect for a quick job. The downside to hand-saws is you will need a different saw for each type of material you need to cut, so if you’re trying to cut wood and sheet metal, that’s an additional cost.

- Jigsaws have a reciprocating blade, and are a great do-it-all saw which we use them quite often on our projects. They excel at making oddly shaped cuts and curves, but aren’t so great if you need perfectly straight cuts. Another advantage to jigsaws is that the blades are small, cheap, and interchangeable so that you can quickly swap between cutting different materials.

- Circular saws are the most heavy duty out of the 3, and are perfect for making long straight cuts. The disadvantage is that you can’t cut curves like you could with a jigsaw, and they’re a little dangerous for beginners. If you’re going to be doing a lot of woodworking, investing in a circular-saw is a good option.

Since jigsaws are one of the most versatile saws, here’s a video with an overview of a jigsaw’s features and some tips on using them.

Choosing Screws

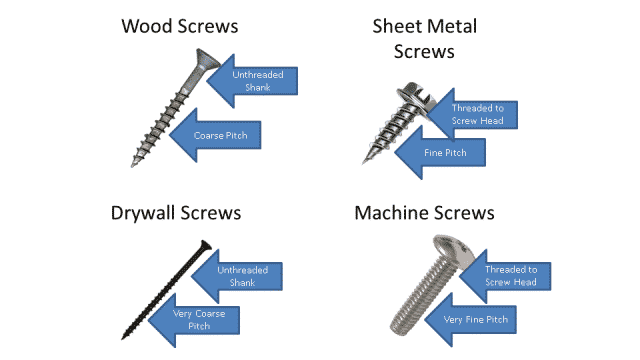

Chances are in any woodworking project, you’re going to have to connect two pieces of material. Screws are ideal for this much better than nails but there are hundreds of different types and sizes, all for different applications. We will review the most common types and applications so that you can quickly determine what type you will need for your project and how to use it.

- Wood screws often have a coarse pitch, unthreaded shank (the bit between the head and the tip), and flat heads. The coarse pitch helps the wood screw tap into the wood and make a solid connection. The unthreaded shank is used so that the head can go flush with the wood beneath it without the threads getting in the way. Flat heads are typically used so that the screw can sit flush against the wood. Most wood screws also require a pilot hole, which you should drill with a drill bit prior to screwing the screw into the wood, find a chart on what size hole to drill for what screw here.

- Sheet metal screws are often much shorter than wood screws since sheet metal typically isn’t very thick. These screws are self-tapping, but still require a pilot hole like wood screws. Sheet metal screws have a fine pitch and are threaded up to the head.

- Drywall screws are typically longer and have coarse threads, more so than wood screws. They too have an unthreaded shank.

- Machine screws come in an array of types and shapes, but are more precisely machined and have higher strengths than other screws. The threads on machine screws are also very fine. When using machine screws you will secure them using a bolt or nut.

Picking the right screws for the job will largely depend on what materials you’re working with. If you stick with screws designed for your material or application, you shouldn’t have any connection problems on your project.

Sanding

Often when working with wood, after cutting it up and drilling holes the surface will be unfinished with unsightly burs and splinters. This is a simple fix with a quick sanding, but with a seemingly endless amount of types and grits of sandpaper and sanding equipment this can get confusing. The kind of object and type of material you’ll sand will also need varying sanders, from smaller detail sanders to big ones like the models mentioned in these reviews for drywall sanders. The main types of sanders we’ll cover are belt sanders, orbit sanders, and hand sanders.

- Hand Sanders are the simplest and cheapest sanding you can do and will likely work well for most small projects. You buy the hand sander which is a plate with a handle (typically ~$5) and then attach pieces of sandpaper to the bottom. The biggest advantage to a hand sander is it’s very cheap. It does take a bit of time, but you can achieve a perfectly acceptable finish with it.

- Orbital sanders are the next level of sanding. They utilize sanding disks for fine control of the surface and are small enough to be useful for tight spaces and small electronics projects.

- Belt Sanders are the heaviest and most powerful sanders here. They drive a belt of sandpaper around and can quickly chew through a lot of material. Belt sanders are best for large flat objects that need finishing, and will generally be too large for our uses.

Whatever type of sander you use, you’ll be using sandpaper. Most sandpaper is aluminum-oxide and comes in different grits. The grit is a measure how fine it is and will determine what you’re using it for. Grits typically range from about 20 to 1000, 20 being extremely course and 1000 being extremely fine. When sanding, if you have a lot of material to remove and really need to smooth things out, a low or course grit will be best. Once you’ve sanded with the coarse grit move to a finer grit, typically up around 200 for finishing.

Painting

Once you’ve built your project and are looking for that professional, finished look, paint can do wonders. There are two types of paint commonly used and choosing one will depend on the material and type of use your project will see.

- Latex paint is a water based paint that is used in general applications. The paint is easy to clean up with just soap and water and easier to apply. It is durable and will adhere to most materials.

- Oil based paint adheres better to surfaces and should be used if you are painting over previous coats of oil based paint. The disadvantage to oil based paint is that the cleanup is harder: paint thinner or mineral oil must be used.

Once you have selected the type of paint that’s best for you, you need to choose a level of sheen which ranges from flat to gloss. The higher the sheen, the more glossy the paint is. As a few general rules of thumb on sheen:

- The flatter the paint, the better it will hide surface imperfections.

- Flat paint makes touch-ups easier and more seamless.

- The glossier the finish, the greater the durability.

- Generally, the higher the gloss, the more washable and scrubbable the surface.